Industrial Assessment Center

The Industrial Assesment Center at Tennessee Technological University is sponsored by the U.S. Department of Energy. We are one of multiple assesment centers thoughout the country.

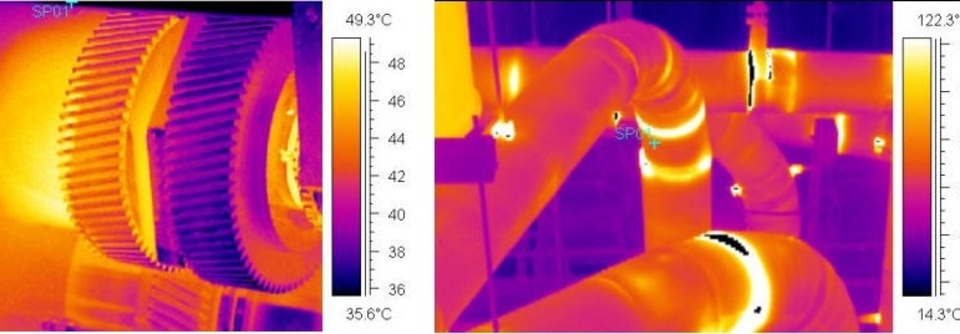

My work with I.A.C. has given me experience with multiple areas of a manufacturing plant including compressed air systems, furnace insulation, heat recovery, boilers, chillers, pumps, variable speed motor retrofits, cooling towers, exhaust systems, capacitor banks, nitrogen consumption, HVAC cooling, lighting retrofits and occupancy sensors, and programmable logic control systems. The majority of my proposed recommendations were implemented by the facilities we visited. Continued correspondence found that those facilities who implemented my recommendations averaged over $10,000 in annual savings and frequently had a payback period of less than two years.

For more information, you may visit “iac.rutgers.edu”. Under the database, you will find that our team at Tennessee Tech (call sign 'TT') currently has a track record of reducing a manufacturing facility’s annual electrical consumption by an average of 3.23%, as well as the annual natural gas consumption by 4.46%. These recommendations are done from data collected in a one or two day on-site assessment.

Review of my credentials will confirm that I have entered a series of industrial plants and successfully reduced their energy consumption. This was achieved by communicating project recommendations that quantified savings opportunities, payback periods, and implemented cost estimates to the plant managers and engineers.

The following are a few of the assesment recomendations that I've presented that were implimented by the respective company.

Demonstrates use of affinity laws to show potential savings in a damper controlled v.s. modulated motor control for a ventilation system.

40HP.pdf

Adobe Acrobat document [310.7 KB]

Demonstrates use of conduction-convective series resistance to show potential savings by adding insulation to a system.

Insulation.GTTank12.Nate.pdf

Adobe Acrobat document [202.7 KB]

Demonstrates use of available sensors and equipment to eliminate excessive ventilation.

Sanding Cabinet, automatic ventiliation [...]

Adobe Acrobat document [192.7 KB]

Demonstrates the recognition of wasted nitrogen gas. Note: elimination was $100,000 annually.

RemoveNitrogenTunnel.Payback.Nate.pdf

Adobe Acrobat document [9.4 KB]